DANAOS Supply has been conceived to minimize cost through complete supply cycle (supply chain) support, efficient evaluation of requisitions, comparison of quotations, order break up strategies, historic cost references and order follow-up to destination. Productivity is enhanced by the paperless distribution of all produced legal document to suppliers.

Digital Services of DANAOS Supply are also available via our DanaosONE Platform

DANAOS Supply is part of the Ship Management Suite and consists of 3 modules:

- PROVISIONS

- STORES

- SPARES

Each one has been optimised for the specific task and reporting requirements. SPARES module is integrated with the PMS and all modules are integrated with the Marine Accounting and Management Information System.

Provisions Control System

Provisions Control System is specially designed for provisions supply and follow up for shipping companies.

- Provides automation of the complete supply cycle. Requisition, quotation, order, delivery, invoice, without data transcription on any intermediate stage.

- Permits grouping per item/category and automatic substitution.

- Optimises supply quantities, supplier selection, order allocation and automatic ordering in accordance with model orders. Information to supply department with pending requisitions critical supply dates, pending quotations, orders, deliveries.Deliveries for time period, historic prices and actual/reference consumption analysis per item/group. Informs management with actual/reference cost analysis per day and man day. Shifting period cash-flow requirements covering last six months and projecting next six.

The entire function of creating the Supply Cycle system, including but not limited to, stores and provisions catalogue creations and Machinery Spare parts catalogues can be outsourced to Danaos, where our data team will collect and harmonise the data before creating them into the system under appropriate departments and catalogues.

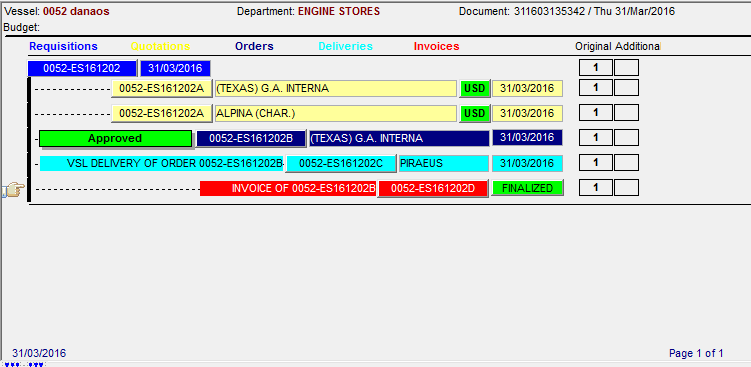

Stores Control System

Store Control Module is specially designed for stores supply for shipping companies.

- Supports departmental division and follow up.

- Provides automation of the complete supply cycle (Requisition-Quotation-Order-Delivery-Invoice) without data transcription in any intermediate stage.

- Optimizes supply quantity and supplier selection process. Informs supply department with pending requisitions per department, critical stores requirements, requisition progress and pending quotations, orders, deliveries, invoices. Deliveries per department for time periods, historic prices. Evaluates quantity requirements with automatic unit conversion. Complete inventory with evaluation. Informs management with moving average cash-flow requirements, covering last six months and projecting next six.

The correct management of onboard supplies, including spare parts, hardware, safety equipment and more is a difficult, yet crucial task. A task that just got easier through the release of DANAOS’ new barcode application.

Danaos BARCODE software is fully synchronized with the DANAOS Green Supply Chain Management Modules in order to ensure consistency between actual inventories and the information contained in clients’ corporate database.

– Assigns a unique code to each item in the DANAOS Supply Module

– Produces unique barcode labels for each item

– Keeps a complete log of which users have performed which task

– During inventory:

– Displays item descriptions on the handheld barcode scanner in order to ensure that the correct item has been scanned

– Gives users the option to scan each item or to scan the item once and then enterthe quantity manually

– Performs a validation between the scanned items and the database entries in order to ensure consistency

– Synchronizes inventory data with vessel databases and then sends it back to the headquarters database through synchronization

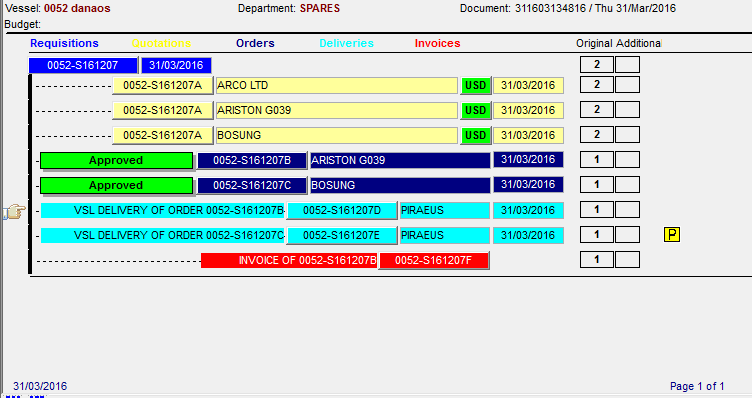

Spare Parts Control System

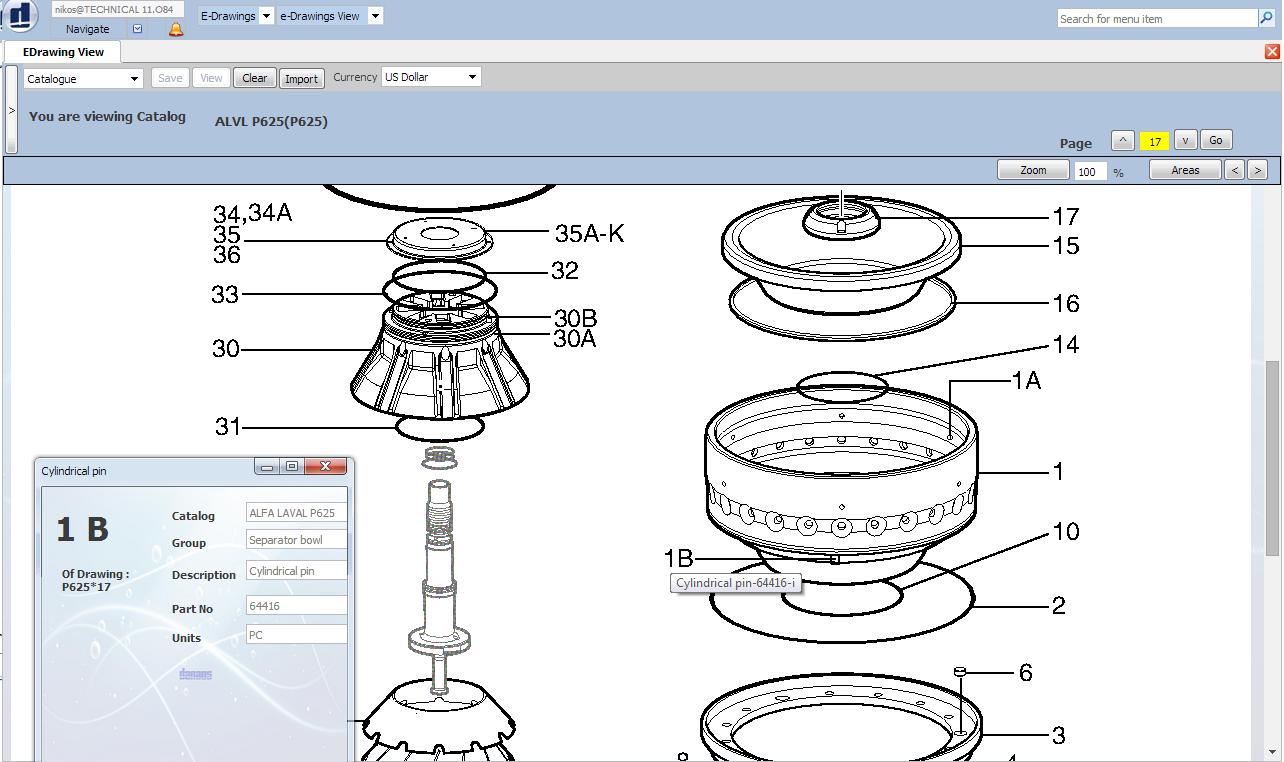

Spare Parts Control Module is specially designed for spare parts supply and integrated follow up for shipping and offshore companies.

Provides automation of the complete supply cycle (Requisition, Quotation, Order, Delivery, Invoice) without data transcription on any intermediate stage. Optimizes supply quantities and supplier selection process.

Information is produced for the technical department and the management. Technical department has full and easy control over requisition and order status pending quotations, orders, deliveries and invoices. Also, complete inventory with evaluation and historical prices paid or quoted. Management has moving average cash-flow requirements covering last six/three months and projecting next six. Complete cost analysis per system is obtained at any stage.